Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 29, 2019 1:23:05 GMT -5

This thread is for anyone wishing to discuss alternative energies.

Such as solar energy and batteries.

Micro hydro generation from stream or river.

Wind turbines.

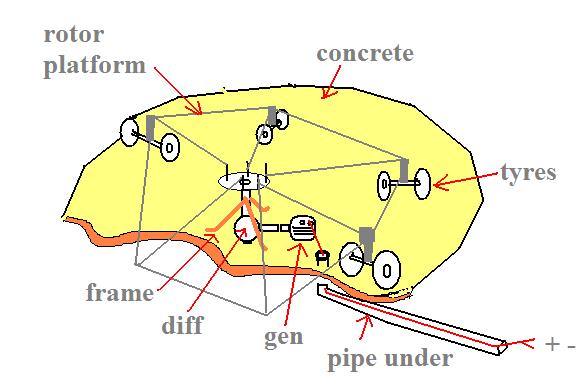

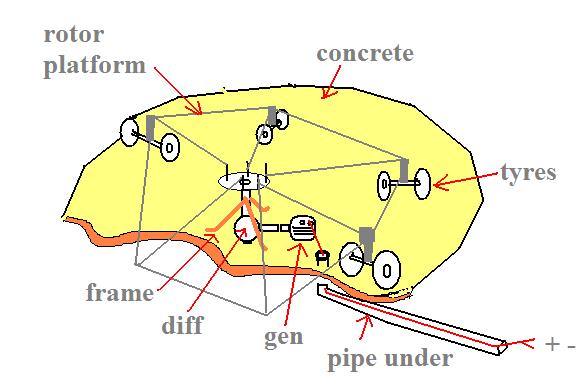

I love designing, creating and solving problems. I hear Dave's has a brilliant vertical wind turbine that has caught my attention. After many hours of thinking, I thought this is perhaps the cheapest best design yet. I like to keep designs simple.

First make a concrete slab, say circular at least 4 metres in diameter, with a 90mm poly pipe placed underneath, near centre to outside. This pipe carries the wires of the generated power to your house.

Get a second hand diff , remove star gears inside, remove one axle, and fix the other axle vertically upwards, with bracing frame. Couple the generator to the diff shaft.

Place steel straps over each stub bolt on the wheel of the axle, so the straps can move up and down but not side to side. This allow the rotor platform to turn without vibrations or the product to be made precise.

Obtain wheels with bearings, and fix them parallel to the spokes radiating outwards from the centre. It is critical these are aligned so the rotor platform turns easily, but the wheels support the weight of the rotor platform.

With other steel straps, link the wheel ribs together making a triangle shape. If you have a 5 wheel stub, you need 5 wheel ribs, if a 6 wheel stub, you need 6 wheel ribs. Once the platform is made check it turns easily and smoothly.

Make the structure on the rotor platform for each wind vane, say 1.5 m high. Purchase 5 or 6 sheet metal, say 1.2 m wide and 2.4 metres long. Bolt one end to the front upright frame and curve each vane to bolt onto another vertical frame upright.

The sheet metal is expensive, but I am not sure what else to capture wind, this makes the curved vanes a full 4m wide and 1.2 m high.

Another idea is to make 40 gallon drums, cut lengthwise, weld two on end, and place these on the outer edge of the platform. This catches less air, but is cheaper to built. The circumference of a 4m rotor platform is 12 metres, so this allows 24 drum vanes to be fitted on the outside, and the distance from centre, enough torque to turn in a small breeze.

Fitting a gear box to the dig shaft allows a geared difference for the generator, just select the gear you want.

Motor wheels and tyres would be best as the bigger wheels, the less torque required to make the rotor platform turn, so being 2 metres from the centre, the platform should turn OK.

It would be a test of weight verses rotor platform diameter.

Instead of two wheels on each spoke, maybe a single motor bike tyre on each spoke might be better?

I wish their was a website explaining such technology like this easily, as its hard to get experience unless you try things yourself.

Have fun creating like our Creator can. We are just not as smart. However it helps us appreciate created things if we try to create ourselves in a humble manner. Shalom |

|

|

|

Post by Dave on Oct 30, 2019 1:26:53 GMT -5

1- This is a wind break for our greenhouse. It has worked so far. 2- It serves as a wind sculpture. 3- last consideration - making electricity. - Only one 60 amp GM alternator with permanent magnets installed on the right hand turbine. Approx 580 watts at 20mph wind. - once I have all 4 alternators installed - should be pushing 3000 watts on a windy day. They are not perfect.2 issuse – I do not weld. I should have made the whole structure out of square tubing welded together. Instead I used 2 5/8 steel pipe, painted to match our chain link fencing. It is too flexible. Secondly, I measured and measured – but static balancing each turbine is/was a challenge. At 25mph or greater, I tie them off because the whole thing begins to wobble like an unbalanced tire.  Unconsidered Error Unconsidered Error The Wobble is more a result of the round pipe structure than my static balance alone It is a 64 square foot sail suspended by 10 round flag poles 12' tall With a good gust of wind the entire assemby leans with the wind After the gust, the upright poles return to upright Repeated gust = a wobble back and forth + any static imbalance = I tie them off at wind speeds of 25 mph or greater. In my next life, I will learn to weld and use 4" square steel tube |

|

|

|

Post by Dave on Oct 30, 2019 3:33:29 GMT -5

I have sat a watched this pendulim swing There is another at the Sithsonian in DC Looks like perpetual motion - is it? The answer is NO - it requires an input The Input is the rotation of the earth! youtu.be/aMxLVDuf4VY |

|

|

|

Post by Dave on Oct 30, 2019 3:40:28 GMT -5

My particular fantasy of energy independence - my own Clock TowerFrom Wiki

The’ Clock Movement’ for England’s Big Ben, designed by Father and son, Edward and Frederick Dent, in 1854 …

1- The pendulum is installed within an enclosed windproof box beneath the clockroom. It is 13 feet (4.0 m) long, weighs 660 pounds (300 kg), suspended on a strip of spring steel 1⁄64 inch (0.40 mm) in thickness, and beats every two seconds.

2- The clock is hand wound (taking about 1.5 hours) three times a week.

3- On top of the pendulum is a small stack of old penny coins; these are to adjust the time of the clock. Adding or removing a penny will change the clock's speed by 0.4 seconds per day

4- The clockwork mechanism weighs five tons. |  |

= The answer to question 9, Exercise 3.7, page 588 – Fields and Functions, A Course in Precalculus Mathematics, J. Richard Lux, 1967, Phillips Academy: Collier-Macmillian Ltd., London, UK I could make a lot of electricity with 37 hp

|

|

|

|

Post by Dave on Oct 30, 2019 12:39:13 GMT -5

The problem with wind power is that it is not constant. However, here in Colorado we have perfect soalar weather 300 days a year and 30-40 days of overcast - www.huffpost.com/entry/colorado-most-magical-state_n_5205600Those 30 or 40 days occure when a 'Front' system spills over the mountains = 2-3 days of perfect wind power. This photo was taken 10/30/2019 at 11am - The front has past - all is calm and the sun is coming back out. I live in a windy alley - 10 miles farther east of me are 31 commercial windmills standing on a ridge. Winds here are usually in the 12mph to 25mph range - Sometimes it is difficult to keep a hat on. In full sun in summer - 400 watts would be enough for our life style Any excess electricity made by a wind generator must be dumped - electric hot water or space heater |

|

|

|

Post by Dave on Oct 30, 2019 12:52:40 GMT -5

In sunny Queensland we have 35 in summer and 12 in winter, that's the temperature in our house. SO we don't use wood heaters or air cons. Just open windows to catch the breeze. Lots of sunshine every day, so solar panels are the way to go. In the foreground of my windmills, burried in the snow, lays 20' sections of 14" dia flexible plastic pipe. All together I have 180' of it. I got it from a guy, who got it from his dad, who bought at a coal mine closing auction - sometime in the 70s. Next summer it will be burried 6' deep (not sure as to length - yet) Length depends on air flow, depends on the energy I want to spend to move it Air drawn in at one end will = 52F or 12C, ground temperature, coming out the other end Our root cellar = 52F year around. My current idea - the outdoor intake should be a omni-directional open mouth weather vane - always pointing the open mouth into the wind I saw an application of this years ago - this guy had a long length of large diameter tin pipe - heating duct (I think) drapped down the side of 150' verical drop. He had covered the pipe with a collection of many different junk yard car glass. It was so UGLY! But inside the house, sitting next to the outlet is was nice warm and the best chair in the place. Because it was verticel - it acted like a solar chimney - hot air rising made its own draft in the day light - and shut itself off at night. taos.org/places/earthship-biotecture/I have visited several Earthship open houses. I visit their Facebook page They have many amazing ideas - they also did a lot of free work in the Phillipines close to people we know. IMO - to do it right - I am not spending $200,000 to build something that has almost no resale value. I have never been in a nice one that was cheap to build. Using tires is a really great idea! The back 3 sides of these structures are just old tires. I started to check into getting tires - they all must approximatly the same size! The distance I would have to cover - the number of trips it would take - the cost of diesle - for me, it was way cheaper to pour a concrete wall. (but - chose another path) |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 30, 2019 13:05:09 GMT -5

Your cold air intake would be a great idea.

On Grand Designs, one person sunk two bore holes close to one another deep into earth, and pushes air down and comes up the other bore, the earth is massive, the temperature down there 15 degrees, so the house air is cooled to 15 degrees, rather than 35 degrees outside. Great idea. Also in winter, the house is warmed to 15 degrees, rather than -10 degrees outside with snow around. It's a simple idea, use the earth as a constant temperature source. Shalom

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 30, 2019 13:13:32 GMT -5

Great plans and pictures.

To avoid wobble, you could get whole car diff and axle. The axle comes wit diff and wheel bearings in a line already. You fix the diff and wheel to your top and bottom frame, and weld brackets in the shaft to hold your wind vane structure. No more wobble.

Or get trailers with both wheels and bearings, and fix outside of wheels to the top and bottom, and use shaft for your wind vane. The precision making of the bearings relative to your shaft is already done for you.

Just my two pennies worth. But love your creative passion here.

Shalom

|

|

|

|

Post by Dave on Oct 31, 2019 19:41:44 GMT -5

This is my neighbor. I took this photo 10/31/2019 1pm He was home and was kind enough to answer some questions: At the heart of his system is a 1,500 gal water tank buried and insulated Inside the tank is a copper coil heat exchanger in a closed loop to the hot water solar panels This closed loop is propylene glycol circulated by two dedicated solar electric panels This hot water system will maintain that buried 1,500 gal tank at 160F and peak of 180F in winter In summer 200F water is coming in from the panels This provides hot water heat for the house A second copper heat exchanger inside the tank provides hot domestic water and water directly from the tank supplies their greenhouse Once up and running - 10 years without a problem Investment cost = north of $10,000 |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 1, 2019 15:05:20 GMT -5

Fantastic. Dealing with extreme snow and cold is a worry and challenge. I see he grows food all year round, heating a green house too. I know you don't have an end of time scenario in the last days, but I do USA is my testing ground of what things will happen. One of those is the tax on water collection. I notice they don't tax on water collected off roofs or asphalt surfaces. Hence I avoid these days pumping out of rivers, creeks, and using bore water. Instead we use an extra large roof to collect water and feed it into a large tank, 150,000 litres. That's 10 metre diameter. I would like to install a second one. Cost? 16,000. Lasts 30 years. If they begin to tax water storage from roofs, we could invest in peltier devices, lots of solar panels and get "Atmospheric Water Accumulation", an alterative technology when things get bad. Maybe one day they might tax the air we breathe?  Have you heard of peltier devices? One could set up say a solar fridge, run copper cold exchanger through it, into a copper exchanger outside with fans, to condense air into water, free way to get 100% pure water to drink. Is this cheaper than boiling in terms of cost? Shalom |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 1, 2019 15:18:44 GMT -5

You could as an idea remove your drum vanes and bolt them vertically, onto a heavy duty truck diff with wheel and wheel bearing. Get engineer to put mounting brackets off to side so it can be mounted vertically. This way all precision spinning is automatically take care of from the diff, and the wheel and its bearings.

Doesn't matter if the bolted wind vanes wobble, the axle won't. Get more power too if they are mount vertically. Don't need support above the stack, but the base will need to be strong, hence a truck diff should hold 5 tonne force load.

Shalom

|

|

|

|

Post by Dave on Nov 2, 2019 10:11:34 GMT -5

Doesn't matter if the bolted wind vanes wobble, the axle won't. Why do you balance car tires? If the rubber tire wobbles - everyone in the car can feel it. Increase the diamater of that tire to 4' - and the resonence accumulates | I love your input - but you are not considering the same dynamic that I didn't in the beginning. By adding height - you increase the verticle tourque. At low wind speed and low rpms your idea would generate a lot of Break Power. With a tradition 3 balded propeller windmill - the baldes never touch the wind - the wind slides past each blade like an aircraft wing generating lift on the blade. Savonius turbing catches and realses 7.5 sq' of wind and back push 7.5 sq' on oncoming wind. It is one heck of sail. |  |

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 2, 2019 14:16:56 GMT -5

Arh yes, but with a tyre with a bubble on it, the bubble pushes against the road and lifts the axle moment, at the axle spins. But a wind wane slightly out of centre turns and pushes against the air, cannot push against the axle. The same principle when I welded an extension onto a drill bit to make it 300mm longer. The speed drill worked ok, but I felt the wobble holding the drill, while drilling in a timber hole, but if I hold the crooked drill in the air, no vibration was felt at all.

Placing the wind vanes vertical increases power onto the drive shaft, because more power in the air the higher your sail is above the earth, old 17th sailing ships did this with square rigging. Modern sailing boats reduce sail area vertically because it makes the forces more manageable, its a cost of weight verses speed, of torque verses acceleration. You could place big drums on the bottom and maybe 20 litres drums higher up??? Not sure? Bolting them, allows getting weight to speed ratio right. You experiment.

What you could do is make another one along my idea, out of welded 200 litres old petrol or diesel drums. If your bracing at the bottom is engineered to be vertical and strong enough, a truck diff and wheel should withstand all the forces of the wind against it. Have a look at how much 44 wheels on a big truck carrying 40 tonnes carries, each wheel at least 1 tonne of force, possibly more. Say 4m by 1m sail area, 4m2 in a wind of 150Km/hr places 200kg force on the sail, is my figures correct? SO an old truck and diff at junk yard, about 20 old drums, and some engineering to make brace points and coupling to shaft, and you all done  |

|

|

|

Post by Dave on Nov 2, 2019 15:52:41 GMT -5

Make your drill bil 4' in diameter - you wont hang onto it

|

|

|

|

Post by Dave on Nov 12, 2019 8:25:17 GMT -5

I hope you can see this - No one was home to ask permission - this photo was taken from across the street It is a Walipini Style Greenhous - the Walipini Indians did this centuries ago to farm in cold climates (wonder where they got their glass?) - I want one! The one you are looking at grows oragnes in January at 9,000' La Vetta, Colorado  |

|